What Is Rebar Corrosion?

Rebar, short for reinforcing bars, are steel bars which are commonly used as tension devices to reinforce structures and materials such as concrete.

This is done as a means to both strengthen and aid the material under tension.

Rebar corrosion is when these reinforcing bars come into contact with chloride ions over time and begin to accumulate rust, thus experiencing corrosion.

Rebar corrosion can cause structural failure.

How To Identify Rebar Corrosion?

Given how rebars lie at the centre of your structure, rebar corrosion can be quite challenging to identify.

This is why identification of such needs to be done through the use of specialised technology.

The award-winning technology we use here at Structural Repairs is non-invasive, non-instructive and ale to provide you with a comprehensive analysis of the current condition of your rebars.

Our technology further allows us to evaluate the corrosion rate and in-situ electrical resistivity of your structure.

In addition, a real-time contour mapping of the condition of your concrete and its rebar is presented and offered to you.

What Causes Rebar Corrosion?

Rebar corrosion is a very common and only natural occurrence among reinforcing bars.

It occurs as a result of the reinforced concrete being exposed to chloride ions which then leads to the premature corrosion of steel reinforcement bars.

The intrusion of chloride ions, which are present in deicing salts and seawater, into the reinforced concrete structures thus causes steel corrosion if oxygen and moisture are likewise available to sustain the reaction.

For further information regarding likely causes of rebar corrosion and for an accurate identification of whether your bars are experiencing corrosion or not please feel free to get in contact with our team of experts who are able to provide you with a free consultation and quotation today.

Why Does Rebar Corrosion Need Repairing?

Although concrete, the most common material where rebars are placed, is a naturally strong material under compression, it does nonetheless have weak tensile strength.

Placing rebar at the core of a concrete structure therefore allows its tensile strength to be significantly increased.

However, over time and as chloride ions come into contact with materials such as concrete and rebar, substantial corrosion is likely to occur.

When steel rebar corrode, the resulting rust ends up occupying a larger volume within the structure than the original steel.

This means that the rebar will lose its strength and ability to make the concrete more tensile.

How Serious Is Rebar Corrosion?

Rebar corrosion is quite a serious occurrence given that it is extremely likely to negatively affect the structural integrity of structure it subsides in.

In fact, the corrosion of reinforcing steel, along with other structurally embedded metals, is the leading cause of deterioration in concrete.

When reinforcing steel bars experience corrosion, the resulting rust tends to occupy a greater volume than the steel, in comparison.

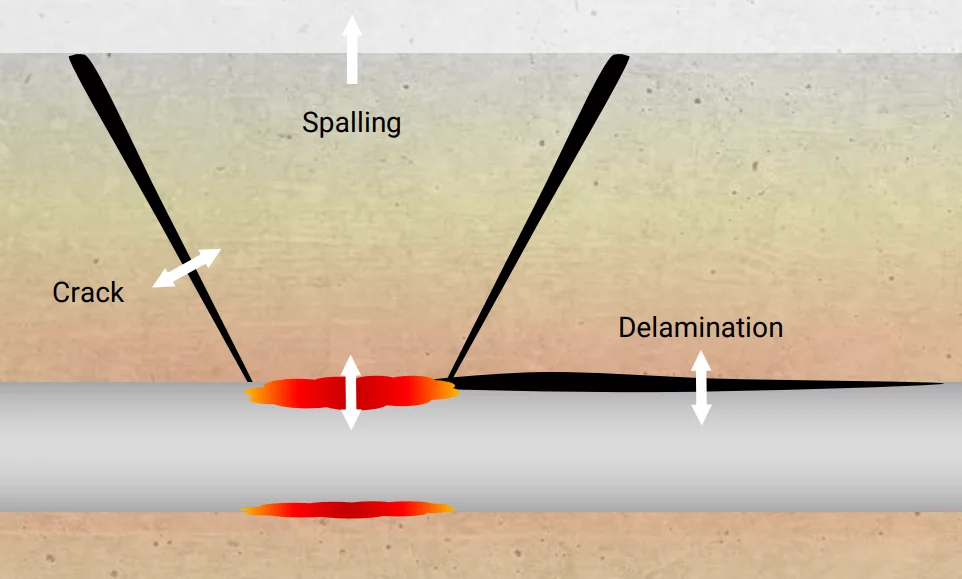

The expansion of the rust creates tensile stresses in the concrete structure which most often than not eventually causes cracking, delamination, spalling and much more – all of which substantially compromise the structural integrity of the structure.

When this occurs, the structure then poses grave danger to its users as is more likely to sustain further and significant damage.

How To Prevent Rebar Corrosion?

There are certain method which can be undertaken as a means to prevent rebar corrosion.

For example, the placement of crack-free concrete with low permeability and sufficient concrete cover is an effective way to do so.

For this, low-permeability concrete can be achieved by decreasing the water to cementitious materials ratio of the concrete.

In addition, the use of pozzolans and slag likewise increase the concrete resistivity and thus reduce the corrosion rate, even once it has already begun.

The use of corrosion inhibiting admixtures, coating of the reinforcement bars with an epoxy resin, and the use of sealers and membranes on the concrete surface are further ways which corrosion can be delayed or prevented.

It is worth noting, however, that sealers and membranes are a preventative measure which have to be periodically reapplied.

Structural Repairs are a leading global specialist