Clinker concrete, once a staple in early industrial and emergency structures, continues to be relevant in specific applications today. While modern materials have largely replaced it, clinker concrete offers distinctive benefits in certain scenarios. Its performance profile may be limited, yet when handled by experienced professionals like Structural Repairs Ltd., it can still deliver reliable outcomes—particularly in restoration projects.

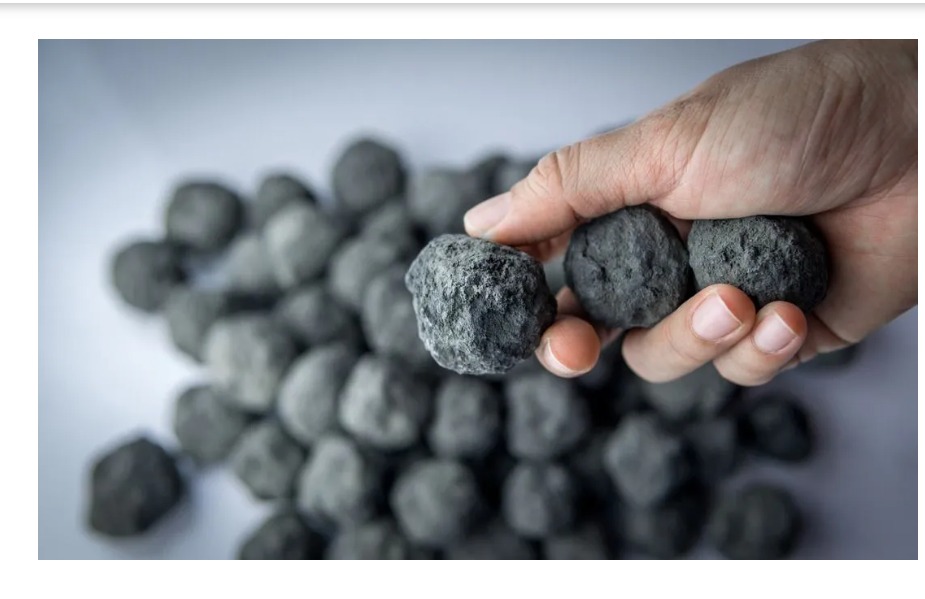

To begin with, clinker concrete was prized for its cost-effectiveness and availability during rapid construction eras. Composed of semi-fused cement lumps called clinker nodules, it was often used as a low-cost by-product of traditional cement production. As a result, it became the material of choice during wartime, industrial booms, and emergency works.

Additionally, clinker concrete’s lower density (1600–2000 kg/m³) made it appealing where weight reduction was essential. This lightweight nature allowed for longer spans without overloading foundations. Furthermore, its high porosity enhanced thermal insulation, an advantage in colder climates where heat retention mattered.

Because of its rough, irregular texture, clinker concrete also offered limited shear resistance, beneficial in emergency builds. It served well in historical industrial structures when material efficiency outweighed durability.

Despite its limitations, clinker concrete can still perform effectively when restored or maintained by specialists. Structural Repairs Ltd. has the experience, tools, and technical know-how to unlock the full potential of clinker concrete. From carefully formulated low-modulus mortars to specialized surface protection systems, the team ensures this legacy material meets modern structural and safety expectations.

Whether it’s evaluating bond integrity, managing moisture behavior, or implementing strategic reinforcement anchorage, Structural Repairs Ltd. delivers tailored solutions that respect the original material while enhancing performance. Their expertise ensures clinker concrete structures are preserved and reinforced with precision and care.

Naturally, clinker concrete is not without drawbacks. Its compressive strength typically ranges from 10–20 MPa, significantly lower than modern concrete (25–50 MPa), making it unsuitable for heavy structural loads.

Its high porosity and low durability result in moisture absorption, shrinkage, and increased vulnerability to frost damage. Furthermore, the bond to reinforcement is weak, increasing the risk of rebar slippage and cracking.

Carbonation resistance is very low, accelerating deterioration. Regular concrete repair methods often fail, requiring gentler materials, specialized repair strategies, and critical surface protection—which is where experts like Structural Repairs Ltd. make a vital difference.

While clinker concrete is no longer a mainstream construction material, it still holds value in specific contexts. With the right knowledge and expertise, it can be restored and reinforced to meet contemporary standards. Structural Repairs Ltd. stands at the forefront of this capability, offering unparalleled insight and proven success in managing and maximizing clinker concrete performance.

Contact Structural Repairs Ltd. today to schedule a professional assessment. Our experienced team will provide expert advice, tailored solutions, and high-performance outcomes that bring aging structures back to life—safely and sustainably.

Get in touch now or visit www.structuralrepairs.com to learn more about our concrete repair services.