Understanding H₂S Gas and Its Role in Construction Projects

Hydrogen sulfide (H₂S) is a colorless, flammable gas known for its distinctive “rotten egg” odor. While it is primarily associated with oil and gas operations, H₂S gas also plays a notable role in certain areas of construction. Its presence can bring both advantages and hazards, making it crucial for construction professionals to understand how to manage it effectively.

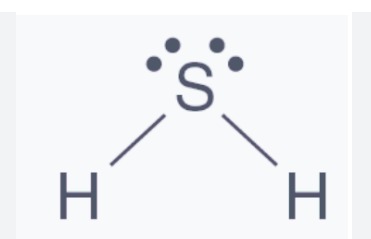

What Is H₂S Gas?

H₂S is a naturally occurring gas produced by the breakdown of organic materials in the absence of oxygen. It often appears in underground pockets, wastewater systems, and contaminated soils. Importantly, even though H₂S is highly toxic at elevated levels, it can be controlled and safely utilized when properly managed.

Applications of H₂S in Construction

First and foremost, H₂S gas has practical applications in ground improvement and soil stabilization projects. In specific geotechnical operations, controlled exposure to sulfur compounds, including H₂S, can alter soil chemistry, leading to better compaction and strength. For example, in some sulfate-rich soils, reaction with H₂S can contribute to forming stable mineral compounds that enhance ground performance.

Additionally, H₂S gas is indirectly relevant during the design and maintenance of sewer systems. Since H₂S forms naturally in sewers and drainage systems, understanding its behavior allows engineers to design corrosion-resistant structures, especially where concrete might otherwise degrade under sulfate attack. In this context, H₂S awareness influences material selection, such as the use of specialized coatings, sulfate-resistant cements, and ventilation systems

Moreover, H₂S monitoring becomes critical during excavation, tunneling, and demolition activities. Construction crews working underground must frequently assess air quality because pockets of H₂S can pose health risks. Therefore, integrating H₂S sensors and alarms in project planning improves overall site safety.

Benefits of Proper H₂S Management in Construction

Managing H₂S correctly offers multiple benefits. Firstly, it extends the lifespan of infrastructure by preventing hidden corrosion. Secondly, it enhances worker safety, minimizing exposure risks during underground or enclosed operations. Thirdly, proactive H₂S control leads to better compliance with environmental regulations, reducing project delays and potential fines.

When contractors recognize and accommodate H₂S risks early in the planning phase, they achieve more sustainable and resilient structures. Consequently, this leads to reduced maintenance costs over time—a significant advantage in large-scale infrastructure projects.

Health and Safety Considerations

Nevertheless, H₂S gas remains highly dangerous when mishandled. Even at low concentrations, it can cause irritation, dizziness, and respiratory issues. At higher levels, it can be fatal within minutes. Therefore, training workers, using personal protective equipment (PPE), and installing real-time gas detection systems are non-negotiable safety measures.

Furthermore, companies must implement emergency response protocols, ensuring that all personnel can evacuate swiftly if dangerous levels of H₂S are detected.

Conclusion

Although often overlooked, H₂S gas plays a subtle but vital role in construction, particularly in soil stabilization, sewer design, and underground operations. By understanding its properties, risks, and advantages, construction professionals can better safeguard their projects and teams.

In conclusion, mastering H₂S gas management is not just about compliance—it’s about building smarter, safer, and more durable structures for the future.

Structural Repairs Ltd. expertly manages H₂S gas risks in underground and sewer-related construction. Our team ensures safe, corrosion-resistant solutions using advanced detection and mitigation systems.

Contact us today for specialist support in projects where H₂S exposure is critical—build with safety, precision, and confidence.