🚨 The ONLY Approved & Permanent

Solution For RAAC Issues In The World 🚨

🚨 The ONLY Approved & Permanent Solution For RAAC Issues In The World 🚨

Save Millions In Construction Costs With

Our Exclusive RAAC Repair Solutions

Save Millions In Construction Costs With Our Exclusive RAAC Repair Solutions

Without wasting money demolishing & rebuilding, compromising safety or waiting for issues to escalate.

Without wasting money demolishing & rebuilding, compromising

safety or waiting for issues to escalate.

Trusted contractor for:

The Modern Day RAAC Crisis

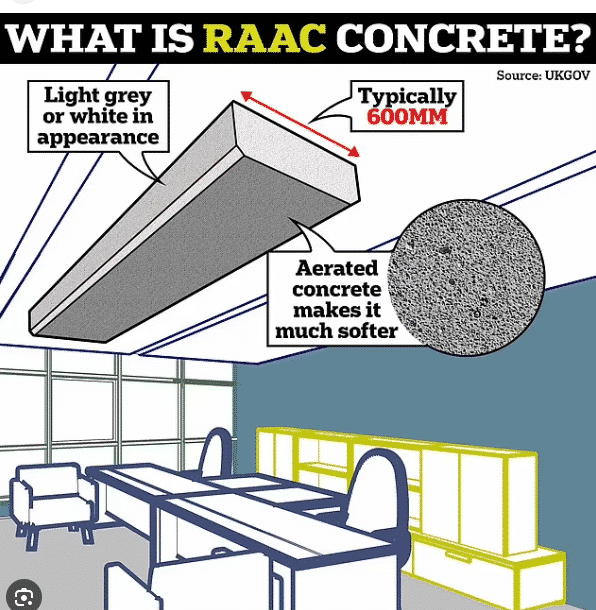

Reinforced Autoclaved Aerated Concrete (RAAC) is a lightweight

material that gained popularity in construction between the

1950s and 1980s.

It was thought RAAC was strong & sturdy…

…but it turns out the air bubbles inside it make it prone to

degradation.

When RAAC is compromised, buildings collapse.

The only solution was to spend millions to demolish & rebuild…

but not anymore!

Reinforced Autoclaved Aerated Concrete (RAAC) is a lightweight material that gained popularity in construction between the 1950s and 1980s.

It was thought RAAC was strong & sturdy…

…but it turns out the air bubbles inside it make it prone to degradation.

When RAAC is compromised, buildings collapse.

The only solution was to spend millions to demolish & rebuild…but not anymore!

Meet the Worlds First & Only Approved Solution to RAAC

FOR THE FIRST TIME WE CAN REPAIR RAAC CONCRETE STRUCTURES BACK TO 99% HEALTH

Patented Composite Technology

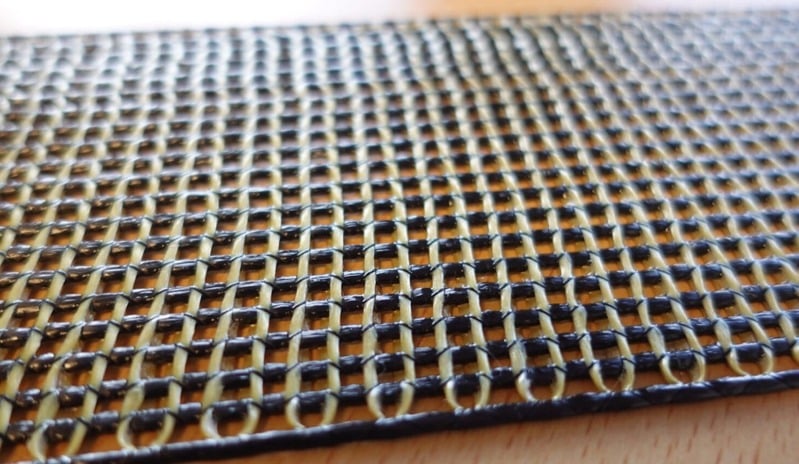

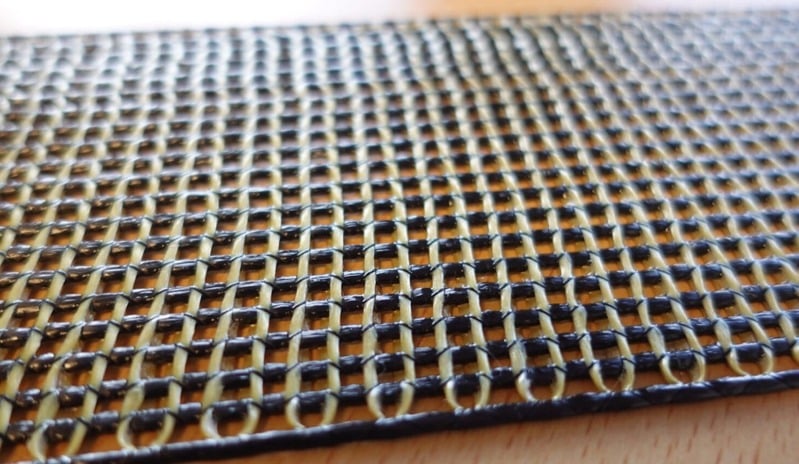

ReGrid (Reinforcement Grid) technology is an innovative solution for commercial and residential concrete structures.

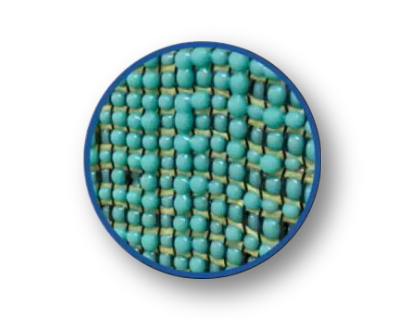

Utilising an industry leading bonding process known as Adhesive Riveting Technology (ART), structural epoxy forms rivets in the open grid created by carbon fibre tows woven with Kevlar® cross threads.

This chemically bonds the product to the concrete structure.

The Fortress line of products have been both lab and the real-world tested to be the strongest and most reliable concrete reinforcement products on the market.

Introducing

Re-Grid Carbon Strips

At Structural Repairs, we have developed an innovative and effective solution to address the major issues associated with RAAC structures.

Our approach involves the use of re-grid carbon strips, which are anchored into the wall and then riveted across the span of the ceiling at spaced intervals.

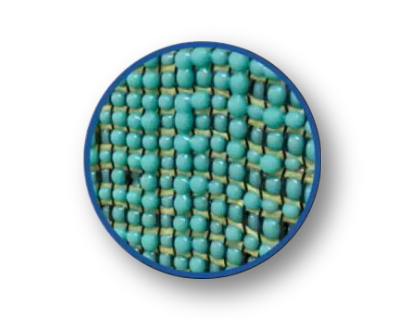

Adhesive Riveting

Technology (ART)

An adhesive forms a chemical

bond to the substrate

An adhesive forms a chemical

bond to the substrate

An adhesive forms a chemical

bond to the substrate

The re-grid carbon strips offer several key benefits:

Corrosion Resistance:

Unlike steel reinforcement, carbon strips are not susceptible to corrosion, ensuring long-term durability of the repair solution.

Versatile Application:

The carbon strips provide additional tensile strength to the RAAC structure, helping to counteract the effects of cracking and spalling.

Enhanced Strength:

Our solution can be tailored to the specific needs of each RAAC structure, ensuring optimal results for every project.

Lightweight and Non-Invasive:

The re-grid carbon strips are lightweight and can be installed with minimal disruption to the existing structure, making the repair process efficient and cost-effective.

From Risk to Resilience with our EXCLUSIVE Re-Grid Carbon Strips

Meet the Worlds First & Only Approved Solution to RAAC

FOR THE FIRST TIME WE CAN REPAIR RAAC

CONCRETE STRUCTURES BACK TO 99% HEALTH

Patented Composite Technology

ReGrid (Reinforcement Grid) technology is an innovative solution for commercial and residential concrete structures.

Utilising an industry leading bonding process known as Adhesive Riveting Technology (ART), structural epoxy forms rivets in the open grid created by carbon fibre tows woven with Kevlar® cross threads.

This chemically bonds the product to the concrete structure.

The Fortress line of products have been both lab and the real-world tested to be the strongest and most reliable concrete reinforcement products on the market.

Introducing

Re-Grid Carbon Strips

At Structural Repairs, we have developed an innovative and effective solution to address the major issues associated with RAAC structures.

Our approach involves the use of re-grid carbon strips, which are anchored into the wall and then riveted across the span of the ceiling at spaced intervals.

Adhesive Riveting

Technology (ART)

An adhesive forms a chemical

bond to the substrate

The adhesive forms rivets

throughout the stitch

Rivets create a mechanical

bond to end

The re-grid carbon strips offer several key benefits:

Corrosion Resistance:

Unlike steel reinforcement, carbon strips are not susceptible to corrosion, ensuring long-term

durability of the repair solution.

Versatile Application:

The carbon strips provide additional tensile strength to the RAAC structure, helping to counteract

the effects of cracking and spalling.

Enhanced Strength:

Our solution can be tailored to the specific needs of each RAAC structure, ensuring optimal results

for every project.

Lightweight and Non-Invasive:

The re-grid carbon strips are lightweight and can be installed with minimal disruption to the

existing structure, making the repair process efficient and cost-effective.

From Risk to Resilience with our EXCLUSIVE Re-Grid Carbon Strips

Public Safety at Stake:

The Immediate Need to Address RAAC Risks

Public Safety at Stake:

The Immediate Need to Address

RAAC Risks

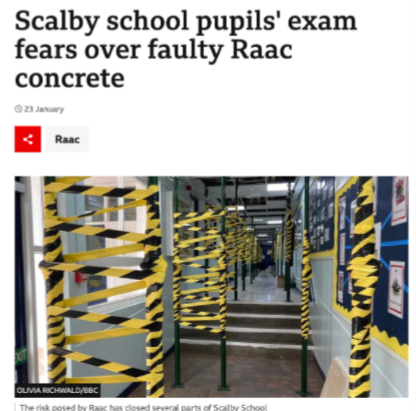

RAAC is causing Schools to crumble & shut

Understanding the unique challenges of RAAC concrete in schools is vital

for ensuring student safety and structural integrity.

More than 234 schools affected by RAAC, the risk of structural issues has

prompted urgent action, leading to government consultations on the list of

schools closed due to concrete problems.

Understanding the unique challenges of RAAC concrete in schools is vital

for ensuring student safety and structural integrity.

More than 234 schools affected by RAAC, the risk of structural issues has

prompted urgent action, leading to government consultations on the list of schools closed due to concrete problems.

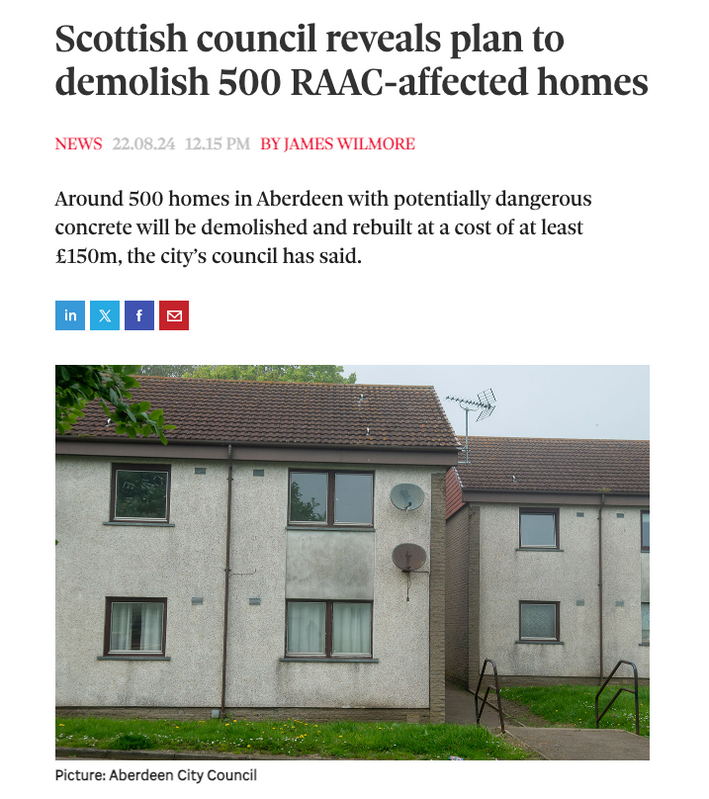

RAAC is causing people to evacuate their Homes

Understanding the potential dangers of RAAC in houses is crucial for homeowners.

Many residential properties built between the 1950s and 1970s may contain this material, which poses risks of structural deterioration and possible asbestos exposure.

Consulting with RAAC surveyors can help ensure safety, protect property value, and address any identified problems effectively.

Understanding the potential dangers of RAAC in houses is crucial for homeowners.

Many residential properties built between the 1950s and 1970s may contain this material, which poses risks of structural deterioration and possible asbestos exposure.

Consulting with RAAC surveyors can help ensure safety, protect property value, and address any identified problems effectively.

RAAC is closing Critical Public Buildings and Infrastructure like Hospitals

RAAC is closing Critical Public Buildings

and Infrastructure like Hospitals

Understanding the impact of RAAC in public buildings is vital for ensuring safety and structural integrity.

Many hospitals and government facilities built using RAAC face risks

of moisture ingress and structural deterioration. The current RAAC crisis highlights the need for detailed assessments across the list of buildings affected by RAAC.

Understanding the impact of RAAC in public buildings is vital for ensuring

safety and structural integrity.

Many hospitals and government facilities built using RAAC face risks of moisture ingress and structural deterioration. The current RAAC crisis highlights the need for detailed assessments across the list of buildings affected by RAAC.

Until now the ONLY option was to demolish and rebuild these structures at an astronomical cost.

Until now the ONLY option was to demolish and rebuild

these structures at an astronomical cost.

Until now the ONLY option was to demolish and rebuild

these structures at an astronomical cost.

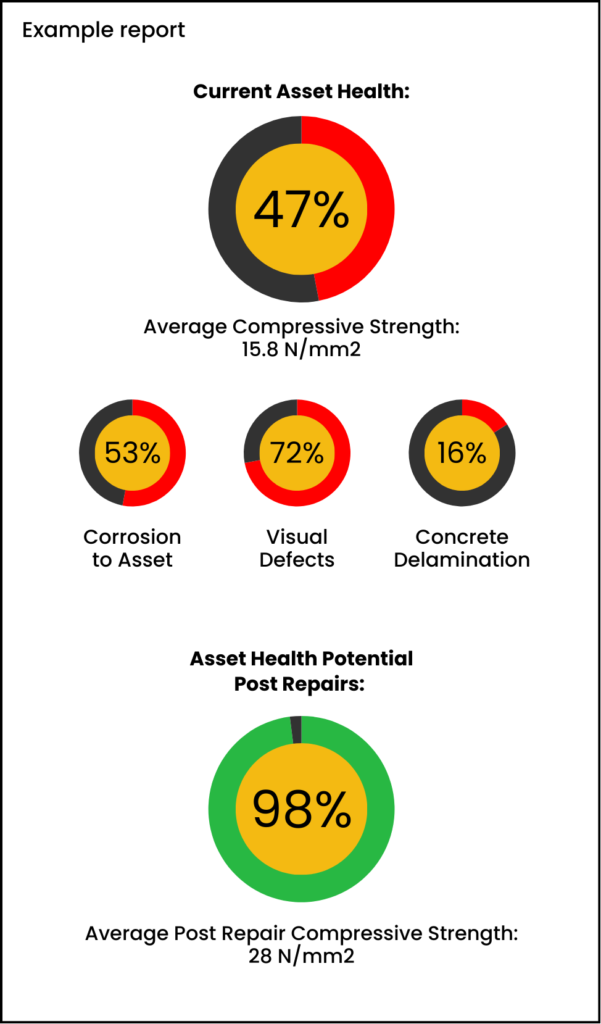

Now we can identify the affected areas & repair them

with re:grid technology in a fraction of the time for

a fraction of the cost...

...AND bring the structure back to 98%+ health & integrity.

Now we can identify the affected areas & repair them

with re:grid technology in a fraction of the time for

a fraction of the cost...

...AND bring the structure back to 98%+ health & integrity.

Understanding RAAC Repair Capabilities

Our RAAC repair services address critical issues such as:

Cracking and spalling:

Prevent further deterioration caused by moisture ingress.

Reduced load-bearing capacity:

Restore the integrity and safety of your structure.

Corrosion of steel reinforcement:

Protect against long-term degradation affecting structural capacity.

Understanding RAAC Repair Capabilities

Our RAAC repair services address critical issues such as:

Cracking and spalling: Prevent further deterioration caused by moisture ingress.

Reduced load-bearing capacity: Restore the integrity and safety of your structure.

Corrosion of steel reinforcement: Protect against long-term degradation affecting structural capacity.

Stay proactive – understand the condition of your concrete assets before issues arise.

Four Reasons why you should choose us to repair and save your RAAC structure...

Four Reasons why you should choose us to

repair and save your RAAC structure...

Why RAAC repair

solutions are essential

For renovation and safety: Understanding what lies beneath the surface is critical for the continuity and safety of your RAAC buildings.

Preventative maintenance: Invest in proactive repairs to extend the life expectancy of your structures.

Streamlined process: Our non-invasive approach means minimal disruption while delivering maximum effectiveness.

For renovation and safety: Understanding what lies

beneath the surface is critical for the continuity and

safety of your RAAC buildings.

Preventative maintenance: Invest in proactive

repairs to extend the life expectancy of your structures.

Streamlined process: Our non-invasive approach

means minimal disruption while delivering maximum effectiveness.

NOT just ‘another’ service

We DON’T rely on outdated methods... we use cutting-edge technology.

Innovative

repairs:

Our exclusive re-grid

carbon strips address

the significant issues

associated with RAAC

structures effectively

and sustainably.

Our exclusive re-grid carbon strips address the significant issues associated with RAAC structures effectively and sustainably.

Smart

solutions:

Understanding the unique challenges of RAAC concrete is essential to ensuring the safety and longevity of your buildings.

Understanding the

unique challenges of

RAAC concrete is

essential to ensuring the

safety and longevity

of your buildings.

Join a

trusted network:

We are the only company offering a permanent repair solution for RAAC concrete, working with esteemed organisations to guarantee quality and reliability.

We are the only company offering a permanent repair solution for RAAC concrete, working with esteemed organisations to guarantee quality and reliability.

As featured in:

Frequently Asked Questions

Find answers to the most frequently asked questions on RAAC concrete

Reinforced Autoclaved Aerated Concrete (RAAC) is a lightweight precast concrete material made from a mixture of sand, cement, lime, and aluminum powder. Known for its insulating properties and used primarily in roofs and walls during the mid-20th century, RAAC has a long history in construction but has recently raised concerns about its structural integrity and durability.

Considering repairs is critical because RAAC can deteriorate over time, leading to potential safety risks, such as structural failures and moisture-related damage. Addressing these issues promptly can help ensure the safety of residents, protect property values, and comply with regulatory requirements.

RAAC repairs can address a variety of issues, including:

- Structural deterioration due to moisture ingress

- Cracking and spalling of panels or surfaces

- Corrosion of embedded reinforcement

- Asbestos concerns in older RAAC products

The repair process typically involves a thorough assessment of the RAAC structure, identifying any areas of concern. Following this, specialized techniques, such as using carbon strips or other reinforcement methods, are applied to restore strength and integrity. The process may also include moisture management strategies and surface treatments to prevent further deterioration.

Yes, when conducted by qualified professionals, RAAC repairs are safe and effective in restoring the structural integrity of affected areas. The techniques used, such as carbon strip reinforcement, have been proven to enhance strength while minimizing disruption to existing structures.

The duration of the repair process can vary depending on the extent of the damage and the specific methods used. However, most repairs can be completed relatively quickly, often within a few days, ensuring minimal disruption to the property.

Yes, after the repair process is complete, you will receive a detailed report summarising the work performed, the condition of the RAAC structure, and any recommendations for future maintenance or monitoring.

While many of the techniques used for RAAC repairs are specific to RAAC structures, some solutions can also be adapted for use with other types of concrete and lightweight building materials. It’s important to consult with a structural engineer or RAAC specialist for specific recommendations.

It is advisable to inspect your RAAC structure regularly, typically every one to two years, or more frequently if there are signs of deterioration, such as cracks or moisture issues. Regular inspections help ensure that any problems are identified early, allowing for timely repairs.

To schedule a consultation for RAAC repairs, you can contact us directly through our website or by phone. Our team will be happy to discuss your concerns, arrange a site visit, and provide expert advice on the appropriate repair solutions for your needs.

No, while both are lightweight materials, RAAC and breeze blocks (or concrete blocks) are not the same. Breeze blocks are typically made from a concrete mix that is denser and does not have the aerated properties that characterise RAAC.