Concrete Corrosion Testing

What Is Concrete Corrosion Testing?

Despite being one of the most widespread man-made materials globally, testing concrete for corrosion has posed a significant challenge.

This is especially critical for reinforced structures as establishing whether concrete is corroding.

The potential corrosion, and the rate at which it’s corroding is crucial.

Failing to do so can lead to significant damage and risks associated with concrete corrosion.

Therefore, testing for concrete corrosion is of utmost importance.

How Is Concrete Corrosion Testing Conducted?

Corrosion testing is essential in establishing the severity and rate of corrosion.

The half-cell potential test is the most common type of corrosion test that measures electrical potential between steel and concrete.

This test identifies areas of corrosion and determines the rate of corrosion.

Despite a few factors that may affect accuracy, such as concrete type and electrode material, the half-cell potential test is still the best and cost-effective method of testing for corrosion.

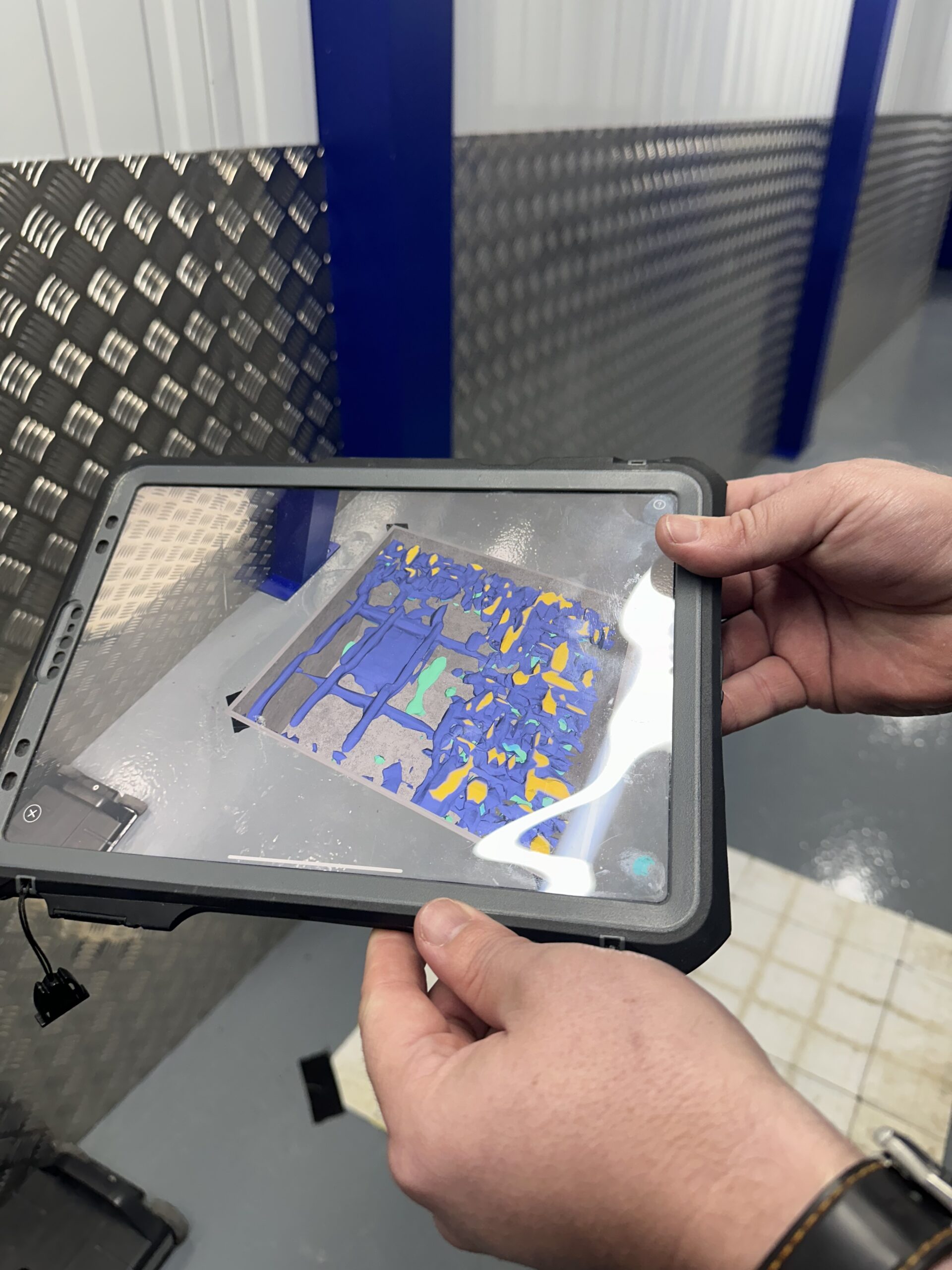

Structural Repairs utilise the latest measuring instruments for on-site mapping of corrosion potential, providing advanced reports on the current and future state of concrete.

The newest non-intrusive testing method identifies active corrosion of rebars by analysing the electrochemical properties of concrete.

What Other Methods Are There to Test Concrete Corrosion?

One method is to measure the electrical resistivity of the concrete.

This can be done by placing electrodes in the concrete and measuring the flow of electricity between them.

Another method is to measure the chloride ion content of the concrete.

This can be done by taking a sample of the concrete and analysis it in a laboratory.

The last method is to measure the carbonation level of the concrete.

This can be done by taking a sample of the concrete and measuring the amount of carbon dioxide that has penetrated the concrete.

What Affects The Rate Of Corrosion In Concrete?

There are many variables that can affect the rate of corrosion in concrete, including the type of aggregate used, the amount of water present, the amount of chloride ions, and the level of carbonation.

The type of aggregate used in concrete can affect the rate of corrosion.

For example, using limestone or shells in concrete can help to reduce the rate of corrosion.

The amount of water present in concrete can also affect the rate of corrosion.

If there is too much water, it can cause the concrete to crack, which can allow for water and chloride ions to enter the concrete and cause corrosion.

The amount of chloride ions present can also affect the rate of corrosion.

If there are too many chloride ions, it can cause the steel reinforcement to corrode.

The level of carbonation can also affect the rate of corrosion.

If the concrete is not properly sealed, carbon dioxide can enter the concrete and cause it to become acidic, which can speed up the corrosion process.

What are the different types of corrosion in concrete?

How can Structural Repairs Can Help?

There are many ways to test concrete for corrosion, but the most common is the use of a concrete corrosion tester.

This test is simple, accurate, and rapid, and can be done in the field with little or no disruption to the concrete.

The device is placed on the concrete surface and sends an electric current through the concrete.

The current will cause the concrete to corrode if there is any metal in the concrete.

The tester will then measure the amount of corrosion and provide a report.

This will flag any issues that need to remedied and a plan of action can be put in place for any repairs that maybe required.

Structural Repairs are able to not only identify the current conditions of concrete in a non-intrusive and efficient manner.

The team can also assist you further with any remedial recommendations that we have suggested.

Structural Repairs are a leading global specialist